News Release

TOYOBO MC participates in Japan’s first actual sea installation experiment of a TLP type floating structure for offshore wind power generation

~Newly developed ultra-high-strength polyethylene fiber IZANAS® ULC receives groundbreaking ClassNK approval~

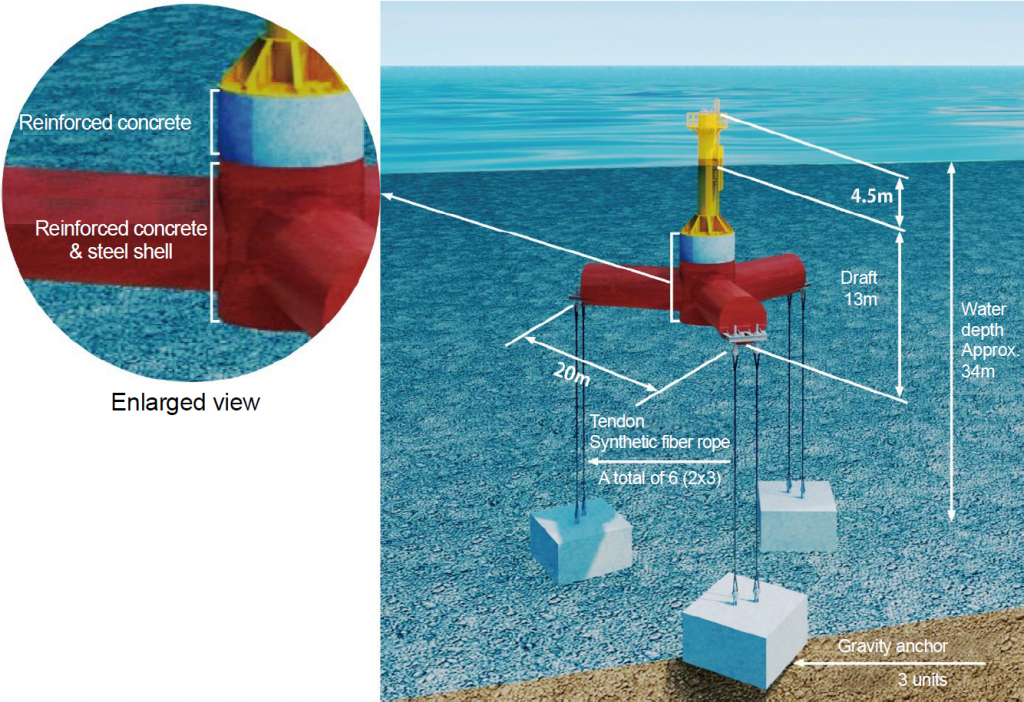

TOYOBO MC Corporation (hereinafter the “Company”) participated in Japan’s first installation experiment of a TLP type (tension leg platform) floating offshore wind power generating facility, which was conducted by Obayashi Corporation (hereinafter “Obayashi”) in the actual sea, off the coast of Aomori Prefecture. Together with Obayashi and Tokyo Seiko Rope MFG. Co., Ltd. (hereinafter “Tokyo Seiko Rope”), the Company plans to conduct joint R&D of the mooring lines that connect the floating structure to the seabed. The mooring lines for the experiment have been manufactured by Tokyo Seiko Rope, using the Company’s newly developed ultra-high-strength polyethylene fiber IZANAS® ULC.

Through this experiment, IZANAS® ULC became the first product in Japan to be approved by ClassNK as a fiber for ropes used in floating offshore wind power generating facilities. While maintaining the same high strength and high elastic modulus characteristics of the conventional IZANAS®, IZANAS® ULC has significantly improved creep*1 resistance, which has been a challenge for this product. As a result, it is expected to be able to stabilize the anchorage of floating structures for a long period of time.

The Company plans to double the annual production capacity of IZANAS® at our Tsuruga plant to 2,000 tons per year by 2030. In promoting the development and production of highly functional materials for the social implementation of offshore wind power generation, we will contribute to the spread of renewable energy and the realization of a carbon neutral society.

*1 A phenomenon in which a solid material undergoes gradual deformation when it is subjected to a continuous load.

1. TLP type floating structure installation experiment background

There are two types of infrastructure for offshore wind power generating facilities: the fixed-bottom type in which the foundation to support the wind turbine is embedded in the seabed, and the floating type in which the wind turbine is mounted on a structure that floats on the sea. At present, the fixed-bottom type, which is suitable for shallow water, is leading the way, but in Japan, where there is limited access to shallow water, the floating type, which is suitable for deep water areas, is expected to gain importance.

Floating type infrastructures differ greatly between floating structure and mooring methods. Infrastructure such as the spar and semi-submersible types are subject to issues including the floating structure experiencing strong pitching and rolling, and low power generation efficiency. On the other hand, the TLP type is expected to have a highly stable floating structure and high power generation efficiency, while also occupying a smaller area in the sea and having less impact on the fishing industry. However, the TLP type is generally difficult to install and has not been used as a foundation for offshore wind power generation in Japan.

2. About the TLP type floating structure experiment

In July 2024, Obayashi installed TLP type floating structure in the waters 3 km offshore of Iwaya, Higashidori Village, Shimokita District, Aomori Prefecture. This TLP type floating structure is connected to an anchor on the seabed by mooring lines, which were made with rope that using IZANAS® ULC. Experiments will verify the stability of the floating structure under actual wave conditions, changes in the tension of the mooring lines, and the applicability of the mooring lines to the floating structure.

3. About IZANAS® ULC

Ultra-high-strength polyethylene fiber IZANAS® is a highly functional fiber made by a gel spinning method.*2 It is applied in fishing lines, ship mooring ropes, safety nets at ballparks, and other applications. In the development of IZANAS® ULC, the conventional fiber-making process was improved to achieve creep resistance while maintaining the light weight, high strength, high elastic modulus, and high weather resistant characteristics of IZANAS®.

- Main characteristics

| Tensile strength | 25 cN/dtex or more |

| Fracture elongation | 3.0 to 5.0 % |

| Fineness | 1760 dtex |

*2 A method of producing ultra-high strength fibers with highly oriented molecules by uniformly dissolving polyethylene, which has an ultra-high molecular weight, in a solution, and then spinning and stretching it with minimal molecular entanglement.

Link Collection

Contact

For inquiries about products and recruitment,

Please feel free to contact us here.